3 main NVH challenges for New Energy Vehicles

What are New Energy Vehicles (NEV)?

New Energy Vehicles (NEV) in general refers to the vehicles using cleaner energy, and the Chinese market defines NEV includes BEV (Battery electric vehicles, such as Tesla), PHEV (plug-in hybrid electric vehicles, such as Toyota Prius) and fuel cell electric vehicle (FCEV).

NEV is the new generation of the automotive market and has aroused heated discussion as well as the attention of NVH development.

NVH, never heard of it?

NVH stands for Noise, Vibration and Harshness, and is a measure of how pleasant a car or truck is experienced while driving.

Noise, vibration and harshness are caused by the car’s mechanical and electrical systems, as well as the car’s interaction with road surfaces and its passage through the air.

The main sources of NVH in a car are its engine, drivetrain and tyres, as well as the sound of airflow along its body.

While noise and vibration can be readily measured, harshness is a subjective quality and is measured either via “jury” evaluations or with analytical tools that can provide results reflecting human subjective impressions.

Interior NVH deals with noise and vibration experienced by the occupants of the cabin, while exterior NVH is largely concerned with the noise radiated by the vehicle, and includes drive-by noise testing.

It is an NVH engineer’s job to change the sound quality, by adding or subtracting particular harmonics, rather than making the vehicle quieter.

Exactly why we sent our own NVH engineering consultant, Yuan Xie to The 3rd China NEV NVH Summit 2019 in Shangai.

Intent of the NEV NVH summit 2019

During this summit, we look to combine the full vehicle NVH development case while taking the power system noise, wind noise and road noise as the breakthrough points to discuss the core technologies of NEV NVH development. We aim and seeking the best NVH solution for NEV, and additionally promote green and sustainable development of the entire automobile industry.

Vehicle NVH is directly related to the experience of drivers and passengers and the performance index of the maximum total mass. It has always been the focus of research and development by all automobile manufacturers, and unmistakably within Engibex’s field of interest.

With the growing importance of electrification NVH performance of NEV is particularly important.

How exciting is China’s NEV market?

Unlike the mature second-hand car market in Europe, Chinese prefer to buy new cars.

Audi for example, claimed that one-third of their newly produced cars are sold to the Chinese market .

With support from the Chinese government, there was a boost in the electrical vehicle industry.

According to a survey in Shanghai last year, around 54.5% of the respondents are planning to buy a NEV in the coming 10 years.

3 main NVH challenges for New Electrical Vehicles?

Car manufacturers, as well as NVH targeted subsystem suppliers, talked about all-rounds issues of this new generation of the vehicle. From their talk and through the discussion with them, they shall the following similar view and I have written down the three main challenges:

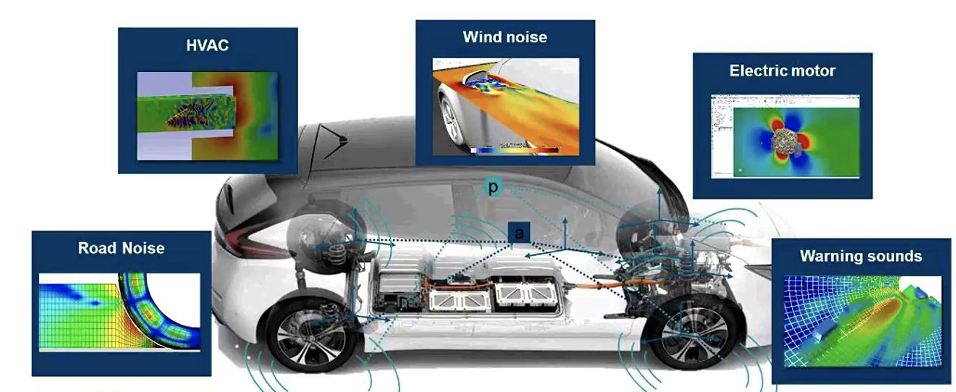

- No masking effect of engine noise

Without the masking the effect of engine noise, which sometimes can even be attractive from supercars, road/tire/wind/transmission noise are more obvious https://www.traditionrolex.com/25 in NEV. For instance, the transmission noise cannot “hide” under engine noise anymore and customers will gear noise more. As a result, all the ratings in the vehicle, such as subjective driver evaluation or acceptable subsystem level noise will all have to be redefined.

- High-frequency tonal E-machine noise

You might have the experience of electric cars which gives a totally different driving experience: you might feel sitting in a spaceship instead of a “car”. There is no low-frequency engine noise anymore but more high-frequency tonal noise from the electric motors. High speed of the motor will cause a howling issue, it is with low (SPL) sound pressure level, but easily recognizable, which is annoying for the customers. Commercially this issue is left for the motor suppliers but there is still no good solution for that.

- Wind noise

- HVAC

- Road Noise

- Electric motor

- Warning sounds

- Big design change requires new product knowledge from scratch

From global dynamics point of view, the whole design is changed: for example, for the BEV (battery electrical vehicle), normally the global stiffness increases and thus damping needs to be adapted as well. On the other hand, BEV tends to use the lightweight design for a better battery range, but reduced material it is not beneficial for sound transmission loss.

From the subsystem level, the main concerns are the noise generated from e-machine/inverter/transmission. Torque ripple, for example, is the main issue in powertrain torsional vibration, and many companies are experimenting and seeking for good solutions. In addition, the other new electronic components added to the vehicle will become the new noise sources: start/stop shock, electromagnetic noise, air compressor noise, etc.

How to reduce noise cancellation?

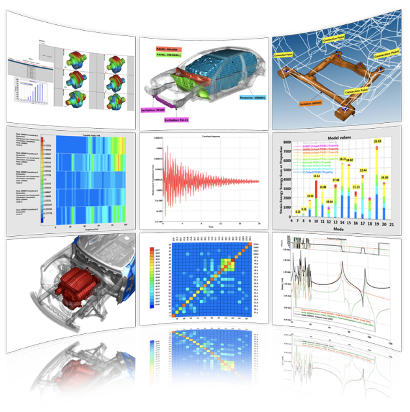

- Design optimization

CAE design + Bench Testing should be the strategy of the product design, which remains applicable from the traditional ICE (Internal Combustion Engine) cars. However, the software typically used for mechanical system modelling also needs to be adapted to electric systems.

- Active noise cancellation

There was a very interesting discussion about active noise cancellation. Senior Manager from Audi Acoustic had a pessimistic view on cabin noise active noise cancellation: the main reason is that the phase is very hard to control in the cabin, and if the phase is not controlled well in the cabin, it can instead amplify the noise. While Chinese companies are still passionate about the future of active noise cancellation techniques: SAIC Volkswagen is showing research results on optimizing the active noise cancellation device arrangement. United Automotive Electronic Systems gave an impressive demonstration of software active noise reduction. To solve the problem of torque ripple, their strategy is to inject harmonic current to the motor. From their vehicle test result, the noise is reduced up to 13dB. I am looking forward to the first generation of active noise cancellation case in the vehicle.

- Design optimization

- Active noise cancellation

- Passive noise cancellation

- Passive noise cancellation

Traditional ways of vehicle noise cancellation such as acoustic package and anti-vibration mounts will still be used for NEV; however, they need to be adjusted for the lighter motor and it needs to go through the development process again. Vibracoustic gave a practical example of rubber flaps as an integrated tuned mass damper, which is low cost and packaging and quite effective.

Conclusion

Biggest takeaway for me was the opportunity to understand the current trend of NVH development in the NEV field.

Of course there are still many issues that remain to be solved:

- Noise: since the torque ripple, electric motor whining and even a small component, such as the air compressor ,can make such high noise, it is challenging but yet rewarding topic for engineers.

- Experience: NVH is an domain which requires a lot of knowhow and experience.

Therefore, the strategy will not change in one day.

We could still apply the old development strategy, in my opinion, but at the same time, we need to gain more knowledge on the new electrical/electronic components and adapt to the new requirements of the product.

We do not have to start all the way from scratch, but at least acknowledge there are new challenges and new chances for NVH.

During the summit, I also got to communicate with NVH experts from all over the world, which is a rare chance during the break, we shared the experience and discussed the technical difficulties of some standard tasks such as EOL testing, and I got valuable advice from experienced experts, which will definitely help me to excel in my current job.

Yuan Xie – NVH Consultant

About the authors

Founder / Managing Director Engibex: David de Brouwer

Yuan Xie

As a consultant from ENGIBEX, I work as an NVH (Noise, Vibration & Harshness) Engineer at TREMEC to help TREMEC identify and solve the noise and vibration issues of the products, in order to meet with the ride comfort standards from the vehicle customers. As a consulting firm, ENGIBEX always encourages the employees to enrich their knowledge and keep up with the current trend of the latest technology. Thanks to the support from ENGIBEX, I was able to join the 3rd China NEV NVH Summit in Shanghai as an NVH engineering consultant in the automotive industry. Attendee and speakers mainly come from China, Germany and the US. From this conference, I was able to know better the customers’ need, to learn about the current available approach and solutions to the noise and vibration issues, so that I could give efficient and professional advice to our client TREMEC.